Services

Global Sinkhole Solutions, USE THEM. Period. Thanks again guys!

Sinkhole Solutions

Our local, American made product solutions will not only remediate your structure, but lift up the local economy.

Helicals:

Helical piers are ideal for applications where there is a need to resist both tension and axial compression forces. Read More

Underpins:

Steel underpinning is an effective solution that takes the load of the foundation system off the soft soils and extends it... Read More

Compaction Grouting:

Compaction grouting can strengthen soil that is weak or has broken apart over many years. Read More

Injection Piers:

Injection piers utilize both the underpinning and the compaction grouting method. Read More

Chemical Grouting:

Chemical grouting is mainly used in areas where shallow sinkholes have formed . Read More

Global SInkhole Hole Solutions Services

Solving an Age Old Problem with Modern Technology

Compaction Grouting

Compaction grouting, widely known throughout the industry as “soil stabilization”, is the most common method used today for remediation of sinkholes, structural leveling and settlement control.

In layman’s terms, compaction grouting consists of pumping a mortar like cement into the ground through steel casing at a low rate and a high pressure to fill any cracks, voids or fissures to seal the limestone and compact the soil.

The injection points for compaction grouting are determined by the geologists and engineers who do the initial testing of the sinkhole, measuring depths of the voids as well as preparing a design plan. The design plan informs our crews of the number of pinpoints, the exact locations, and depths of the grout casing to be installed.

DrillingThe drilling itself is performed using specially modified equipment that is specific to the foundation repair industry. The rigs are equipped with high flow hydraulics that allow for use in constricted spaces such as porches, garages and carports. The drilling rig allows for grouting pipes to be installed either vertically or diagonally to access the sinkholes precise location. Once the grout casing has been properly installed a mortar like mixture is injected into the ground at a low rate and under high pressure in order to compact and displace the loose soil. As the sinkhole is filled with grout, the grout casing is then removed to allow the grout to rise and fill the entire void; this allows the soil to compact above the limestone. Upon completion of a compaction grouting project, the injection points are covered up, the job site is secured and cleaned and the customer is given an inspection for approval.

DrillingThe drilling itself is performed using specially modified equipment that is specific to the foundation repair industry. The rigs are equipped with high flow hydraulics that allow for use in constricted spaces such as porches, garages and carports. The drilling rig allows for grouting pipes to be installed either vertically or diagonally to access the sinkholes precise location. Once the grout casing has been properly installed a mortar like mixture is injected into the ground at a low rate and under high pressure in order to compact and displace the loose soil. As the sinkhole is filled with grout, the grout casing is then removed to allow the grout to rise and fill the entire void; this allows the soil to compact above the limestone. Upon completion of a compaction grouting project, the injection points are covered up, the job site is secured and cleaned and the customer is given an inspection for approval.

Chemical Grouting

Chemical grouting is mainly used in areas where shallow sinkholes have formed and compaction grouting is not an option, such as around pools, sidewalks and other such areas where compaction grouting presents too much of a risk to the structure.

Chemical grouting requires much less pressure than compaction grouting, and is able to penetrate the smallest voids, pores and shallow sinkholes that the mortar like mix used in compaction grouting cannot. During chemical grouting, polyurethane solutions and epoxy injection resins are used to expand and strengthen the underlying soil as well as create barriers that are impermeable to water and other such elements. Due to the use of smaller injection pipes, the time frame of completion of chemical grouting is much quicker than that of compaction grouting. Using state of the art equipment, materials and the expertise of our staff, chemical grouting not only repairs the damage but also extends the life expectancy of your infrastructure.

Chemical grouting requires much less pressure than compaction grouting, and is able to penetrate the smallest voids, pores and shallow sinkholes that the mortar like mix used in compaction grouting cannot. During chemical grouting, polyurethane solutions and epoxy injection resins are used to expand and strengthen the underlying soil as well as create barriers that are impermeable to water and other such elements. Due to the use of smaller injection pipes, the time frame of completion of chemical grouting is much quicker than that of compaction grouting. Using state of the art equipment, materials and the expertise of our staff, chemical grouting not only repairs the damage but also extends the life expectancy of your infrastructure.

As with any project Global Sinkhole Solutions is involved in, upon completion the worksite is secured, cleaned and presented to the customer for inspection and approval.

Underpinning

Underpinning

Underpinning is a very effective method of foundation stabilization that transfers the weight of the auger pipestructure to a deeper and denser foundation, with the use of hydraulically inserted steel underpins. Our present themselves as an obstacle, such as sod, trees, shrubs, concrete sidewalks etc, and then excavating a small area close to the structure to access the structure’s foundation.

After conferring with the site engineer and analyzing the auger pipe2plan, a depth is found that is capable of supporting the weight of the structure and braces are set into place under the foundation. Piers are hydraulically driven into the ground until bedrock or a level of stratum capable of supporting the structures foundation is reached. Once the desired depth is obtained the weight of the structure is transferred to the piers.

Injection piers

Injection piers utilize both the underpinning and the compaction grouting method. Injection piers are installed using the same techniques as underpinning. The key differences between underpinning and injection piers are the steel piers themselves. The steel piers used for injection grouting are specially designed perforated piers that allow grout to be pumped into the sinkhole through the piers themselves. This procedure provides an anchoring force for the steel piers, prevents downward soil flow, infiltrates the soil, and seals the limestone surface. Using the two techniques together creates one of the most stable methods of foundation repair in the industry today.

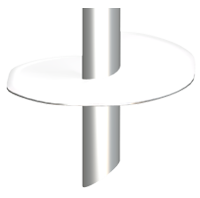

Helical Piers

Helical Piers

Helical are superior to many other new construction structural reinforcement methods, facilitation soil stabilization and foundation settlement. We use rigid three-bolt coupling which connects helical lead sections and extensions makes the pile resistant to bending, unlike the pin and bolt coupling found in square-shaft helical pile solutions.